AWE Tuning Brand Spotlight: Precision Performance, Built by Passion

AWE Tuning began as a Euro-focused performance shop, but their journey has seen this incredible brand evolve into a performance icon that serves every enthusiast.

AWE Tuning began as a Euro-focused performance shop, but their journey has seen this incredible brand evolve into a performance icon that serves every enthusiast.

Learn how suppliers use BigCommerce to scale D2C sales, and how the PDM Automotive connector makes it easier than ever to go live fast—with accurate data and fitment built in.

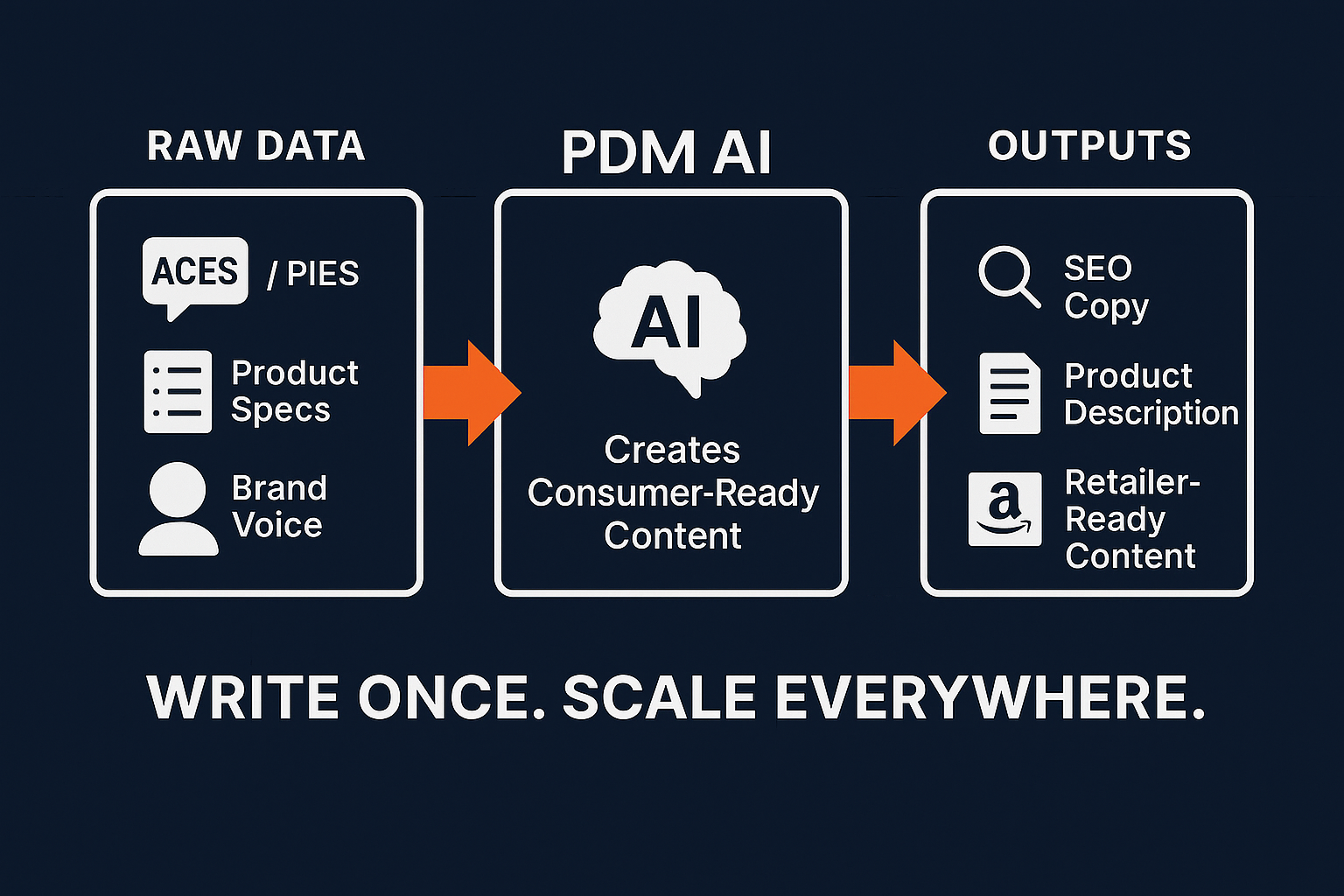

Too many suppliers rely on raw specs to sell their products—but consumers shop based on benefits, not part numbers. Learn how PDM AI helps brands turn technical data into SEO-ready, shopper-friendly content that sells across every channel.

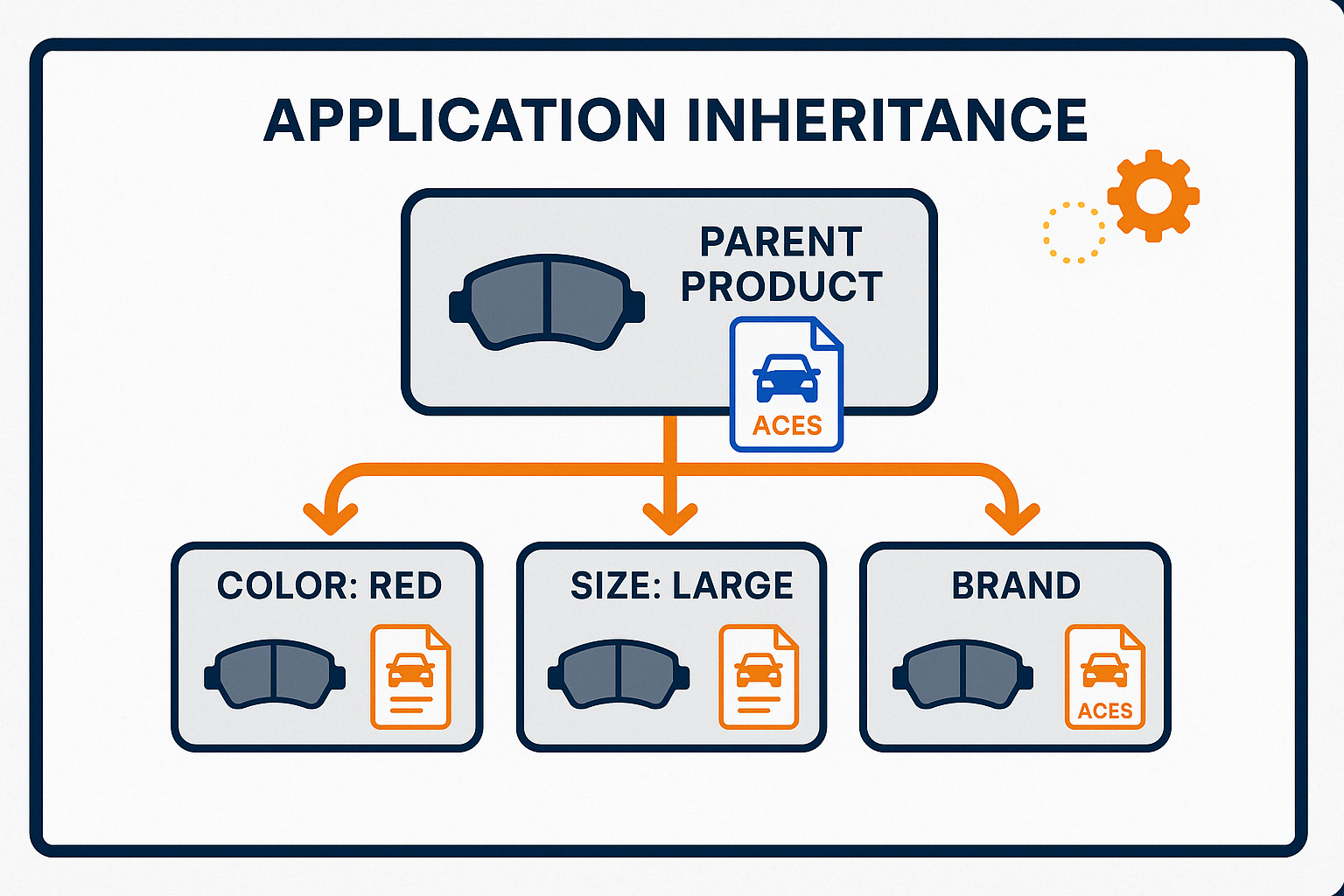

Stop entering fitment data product by product. With Application Inheritance, you can manage one set of vehicle compatibility records and share it across related SKUs—saving hours and boosting accuracy.

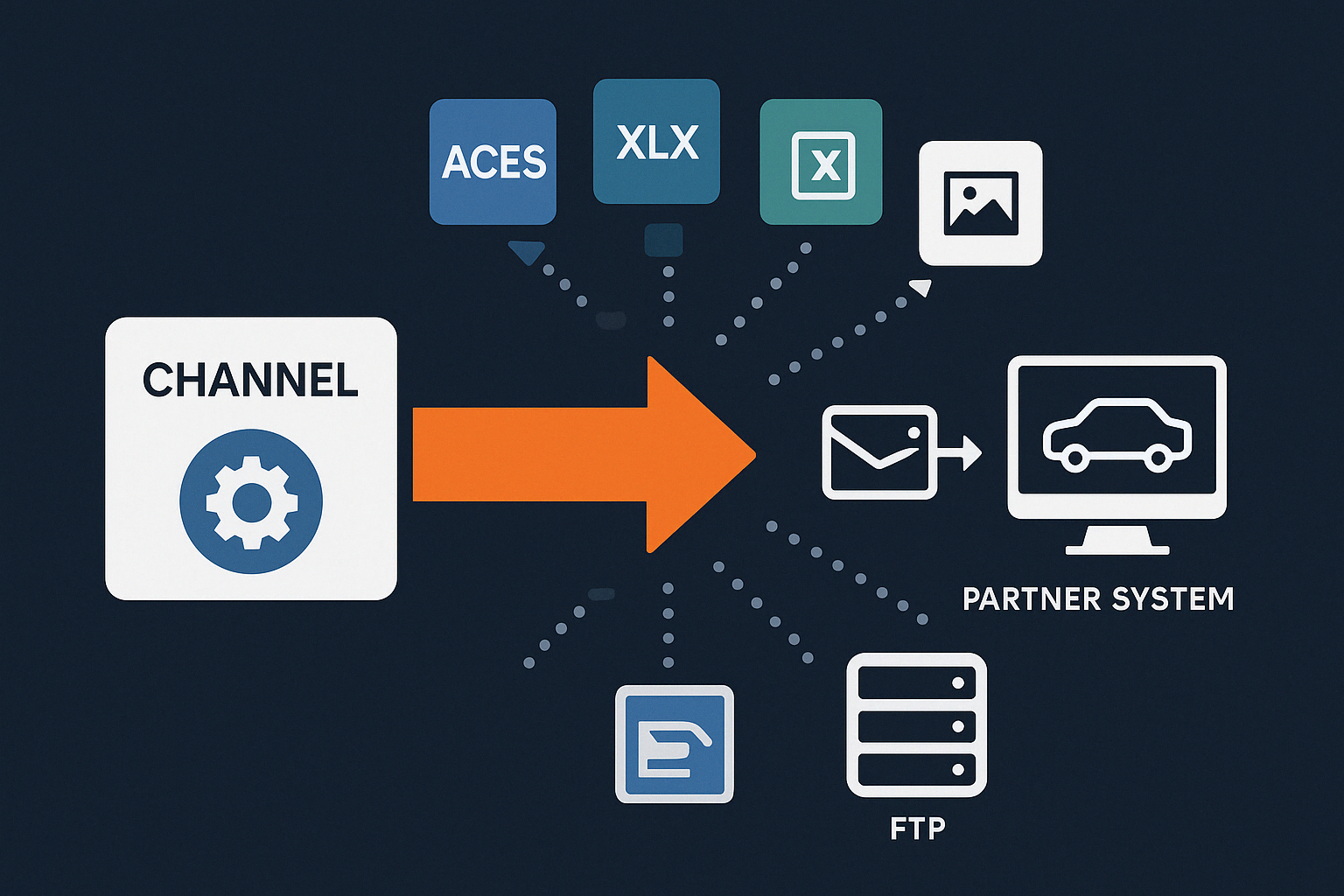

Stop sending spreadsheets manually. With PDM’s Channels, you can automate ACES, PIES, Excel, and asset delivery on your schedule via FTP or email.

Export Builder Plus lets you build reusable export templates tailored to your internal systems or partner requirements—so your product data gets where it needs to go, fast and clean.

© 2023 All rights reserved

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.