One of the most convenient things about shopping for parts online as a consumer is the sheer volume of products available for vehicles, all available at the push of a button.

On the frontend, a consumer uses a filtering tool to select the year, make, model, and trim, and from there, the site returns a wide variety of parts available for the specific vehicle. As simple as this looks to the consumer, on the backend, a complex series of operations accurately and effectively filters down thousands of potential parts into a handful of parts that will fit a customer’s vehicle.

Established product data standards like ACES and PIES help standardize required product information. Still, using ACES and PIES data to filter for the year, make, and model on a website is complicated without a carefully designed PIM platform that integrates with popular eCommerce platforms like Shopify or BigCommerce.

Let’s dig deeper and learn how companies like PDM Automotive can help aftermarket companies get accurate year, make, and model search results for their website.

Understanding the Importance of Accurate Search Results

When it comes time to sell parts and components for vehicles online, there is nothing more important than providing accurate fitment information for consumers.

Accurate and reliable information is crucial for the success of an automotive parts website. Incorrect deliveries not only result in dissatisfied customers but also harm the retailer’s reputation and can lead to a decline in future sales. Therefore, ensuring precision in this fundamental aspect is essential for thriving in the online marketplace.

The Role of Data Standardization

To help aftermarket companies ensure accurate fitment data, the ACES and PIES standards were developed by the Auto Care Association as the internet became the new standard for shopping.

ACES (Aftermarket Catalog Exchange Standard) and PIES (Product Information Exchange Standard) are data standards used in the North American automotive aftermarket industry to efficiently manage and exchange product data and details.

Here’s how they break down.

ACES (Aftermarket Catalog Exchange Standard):

Purpose: ACES standardizes the industry’s vehicle application data. This means ACES used for cataloging which parts fit which vehicles.

Content: ACES includes details about vehicle make, model, year, engine, and other specific characteristics relevant to part compatibility.

Use: Companies use ACES to ensure that their parts correctly match vehicles. It helps retailers, wholesalers, and manufacturers avoid errors in part fitment, leading to fewer returns, higher customer satisfaction, and more efficient inventory management.

PIES (Product Information Exchange Standard):

Purpose: PIES standardizes how product attribute data is communicated. This includes prices, descriptions, images, dimensions, weights, and other product-specific information.

Content: It doesn’t deal with vehicle fitment but rather the parts. It ensures the product information is accurate and detailed enough to engage consumers.

Use: Companies use PIES to provide comprehensive product information, making it easier for customers to find, compare, and purchase products. It’s crucial for e-commerce, cataloging, and maintaining product data integrity.

Implementing PIM System Software & APIs

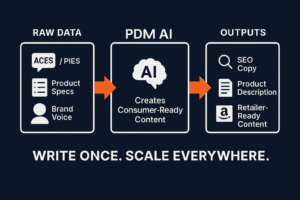

Product Information Management (PIM) software helps maintain a single source of truth for product data. It is a crucial tool to get year, make, and model information correct on any parts website.

Instead of managing ACES and PIES product data manually with spreadsheets, PIM systems allow companies to not only manage data at the source but also transmit it wherever they choose. Possible scenarios include resellers on marketplaces such as Amazon, eBay Motors, or even their direct website. When a customer lands on a website and types in their year, make, and model information, the website relies on information provided by the PIM platform.

APIs (Application Programming Interfaces) provide the bridge that connects an eCommerce website to a PIM system. PDM’s team builds custom APIs that are designed to work with the often laborious and complicated processes at eCommerce providers and provide a host of other benefits:

- Allow the PIM system to connect and communicate with other business systems like ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), e-commerce platforms, and digital asset management systems.

- Product information is consistent and up-to-date across all platforms, automatically syncing changes made in the PIM to other systems and vice versa.

- APIs use standardized protocols and data formats (like JSON or XML) to ensure that different systems understand and correctly process the exchanged information.

- Automate routine tasks such as updating product listings, price changes, and inventory adjustments, reducing the need for manual intervention and minimizing the risk of errors.

- Allow developers to build custom integrations and functionalities tailored to the specific needs of a business, making the PIM system more flexible and adaptable.

- APIs can provide real-time access to product information, ensuring that customers and business partners always have the most current data.

Implementing a Year, Make, and Model Filter

Think of a Year, Make, and Model (YMM) filter as one part of a continuous cycle. Data is fed into the PIM and delivered via an API to the YMM tool that shows on an eCommerce site. Information such as inventory is then fed back to the PIM, and so on.

Implementing the YMM Filter

Frontend Development: On the website’s front end, design the YMM filter interface. This typically involves dropdown menus or a form where users can select their vehicle’s year, make, and model.

Dynamic Filtering: Implement dynamic filtering logic so that the make and model options are contextually updated based on the selected year, and the model options are updated based on the selected make.

Backend Development: Develop APIs to fetch the relevant data from the database based on user selections. The API should return the products compatible with the selected vehicle.

Optimize for Performance: Ensure the backend is optimized for performance, as filtering through large datasets can be resource-intensive.

Several professionals are involved in the process of designing and implementing a YMM tool:

- Web Developers/Engineers

- Frontend Developers

- Backend Developers

- Product Information Manager (PIM) Specialists

- UX/UI Designers

- (QA) Engineers/Testers

- Project Managers

- SEO Specialists (for e-commerce or large-scale platforms)

PDM Automotive Helps Bridge The Gap

PDM Automotive emerges as a pivotal solution in an intricate ecosystem, ensuring that customers effortlessly pinpoint exact matches for their vehicle parts through the implementation of a sophisticated Year, Make, and Model (YMM) filter.

At the heart of this precision lies PDM Automotive’s adept use of established product data standards like ACES and PIES. These standards are not just about data uniformity; they are about ensuring every piece of information, from the vehicle’s year, make, and model to the most intricate part details, is accurate, reliable, and readily accessible. This precision is critical, not just for customer satisfaction but for the reputation and success of automotive businesses in the digital marketplace.

However, the real difference is PDM Automotive’s robust PIM software and custom-built APIs. These technologies transcend traditional data management, offering a seamless, real-time sync of extensive product databases with eCommerce platforms such as Shopify or BigCommerce. This integration means that when a customer specifies their vehicle details, the website doesn’t just respond; it anticipates and aligns with the customer’s needs, filtering through thousands of parts to present a curated list of perfect matches.

At PDM Automotive, we’re not just about providing a tool; we’re creating a dynamic ecosystem that ensures continuous data flow and relevant, timely solutions for every customer.

Contact PDM Automotive today to learn how to transform your automotive aftermarket business.