Tariffs may be political, but their impact on your catalog is practical.

With trade regulations in constant flux, managing catalog content has become a critical part of risk management and revenue protection. For automotive brands and suppliers, it’s not just about staying compliant. It’s about staying ready.

From brake rotors to electrical components, even minor changes in data quality can trigger major cost issues. Here’s how top brands are preparing their catalogs to stay ahead of the uncertainty.

Enter and maintain Country of Origin metadata

Country of Origin (COO) data is no longer just a “nice to have.” It’s a requirement for many channels, especially when tariff rates vary by country.

Missing or inaccurate COO fields can lead to:

- Incorrect landed cost calculations

- Delays at customs

- Unintended exposure to tariff hikes

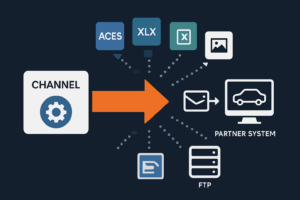

Brands using a platform like PDM Automotive should ensure COO is tracked at the part level and included in all exports, whether ACES, PIES, or custom formats. o triggering warning requirements due to their composition or manufacturing processes.

Keep pricing up to date across all channels

Effective dates are a simple but powerful tool.

They let you schedule updates in advance, whether it’s a pricing adjustment, material change, or regulatory shift.

By planning ahead, you can:

- Avoid last-minute scrambles when new tariffs are announced

- Give your partners time to adjust their systems

- Stay in sync with your supply chain and accounting teams

Communicating updates in advance also builds trust and reduces operational friction. NIA WARNING” to help consumers understand the regulation is California-specific.

Material attributes can impact tariff classification

It’s not just where a part is made that matters. What it’s made of can determine whether it’s subject to a specific tariff.

Incomplete or inconsistent material fields can lead to:

- Misclassification under the Harmonized Tariff Schedule (HTS)

- Unexpected costs due to incorrect duty rates

- Lost time correcting paperwork or relabeling shipments

Make sure material composition is clearly defined in your catalog, especially for items like fasteners, gaskets, suspension components, or rubber parts.

Focus on the fundamentals

When things feel uncertain, tightening up the basics becomes your best move. That means ensuring your catalog content is complete, validated, and mapped properly across every required attribute. Fitment, pricing, materials, compliance fields, and core specs all need to be buttoned up.

Strong fundamentals are what make it possible to respond quickly when tariffs shift or trade rules change. A complete, organized catalog allows your team to take action without hesitation.

The best defense against tariff uncertainty is a proactive, data-first strategy

Unpredictable tariffs don’t have to equal unpredictable operations. Brands that invest in catalog discipline and data visibility are better equipped to stay ahead of shifting regulations.

From COO to pricing, from material specs to scheduling updates, every field in your PIM plays a role in protecting revenue and reducing risk.